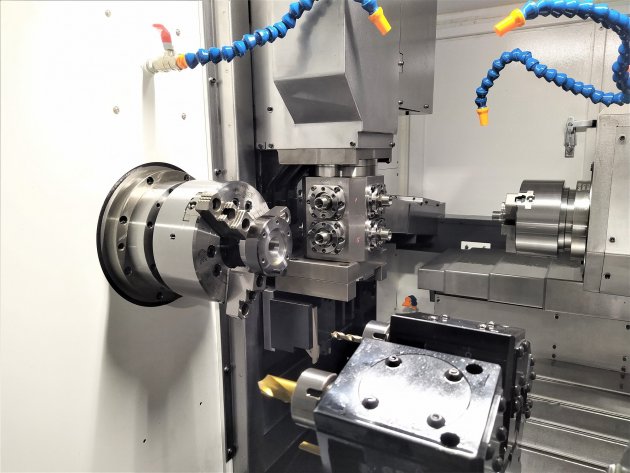

The 2STB CNC Multi-tasking turn mill center with dual-spindle, power turret and B-axis driven tool provide a wealth of processing tool configurations. Turning, drilling, milling, and various special power tools can be used to complete all processing at once, decrease the processing error of setup many times, boost production efficiency. The CNC turning and milling machine have wild range of application, in order to meet the processing requirements of various industries for the future, and complex machining parts, such as precision parts of aerospace technology, artificial joints for medical, water pumps and electronic parts.

2STB CNC Multi-tasking turn mill center Feature

Main Spindle Capability

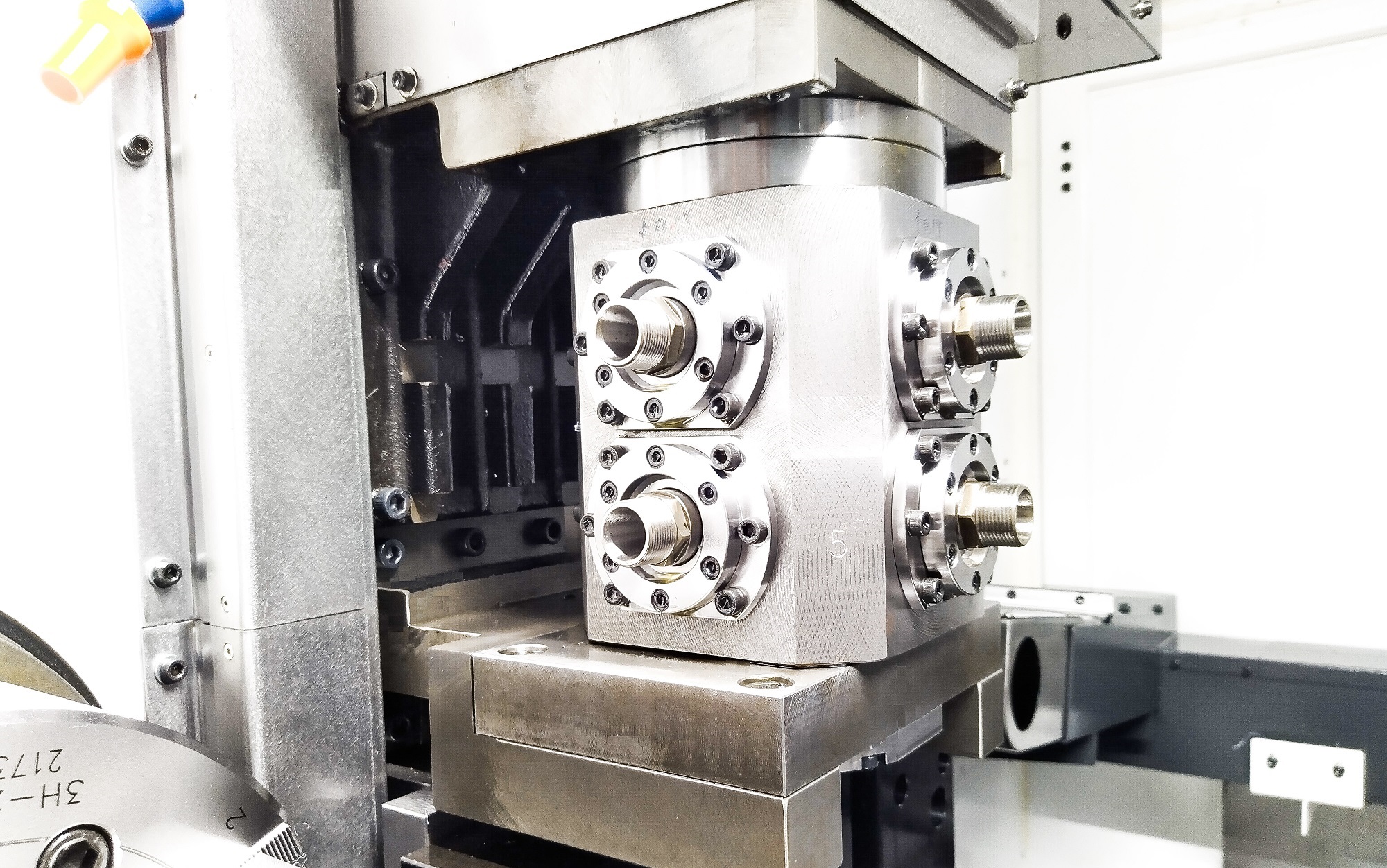

More complex work part can be dome in one machine called, 2STB CNC Turning & Milling Center, provide 2 equal size spindles. It can offer flexible machining requires to help customer solve lots of processing issue. Spindle motor is FANUC α type to offering wild range of torque for high power performance.

Sub Spindle Capability

5 O.D. tools holder of □20 mm, 5 I.D. tools holder of Ø25 mm and B axis driven tooling with 8 driven tools set of ER-20 interface. Providing more machining flexibly.

Control System

FANUC new generation touch screen to easy operate by Intuitive design, 15" touch panel display mounted with FANUC, large screen offer more infomations. Operation switches and buttons are placed in functional operation panel, more convenient button in machining panel. Large machining space to easy picking workpiece, tool exchange, operation safety and higher work performance.

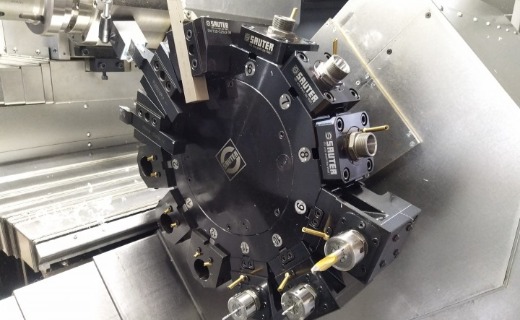

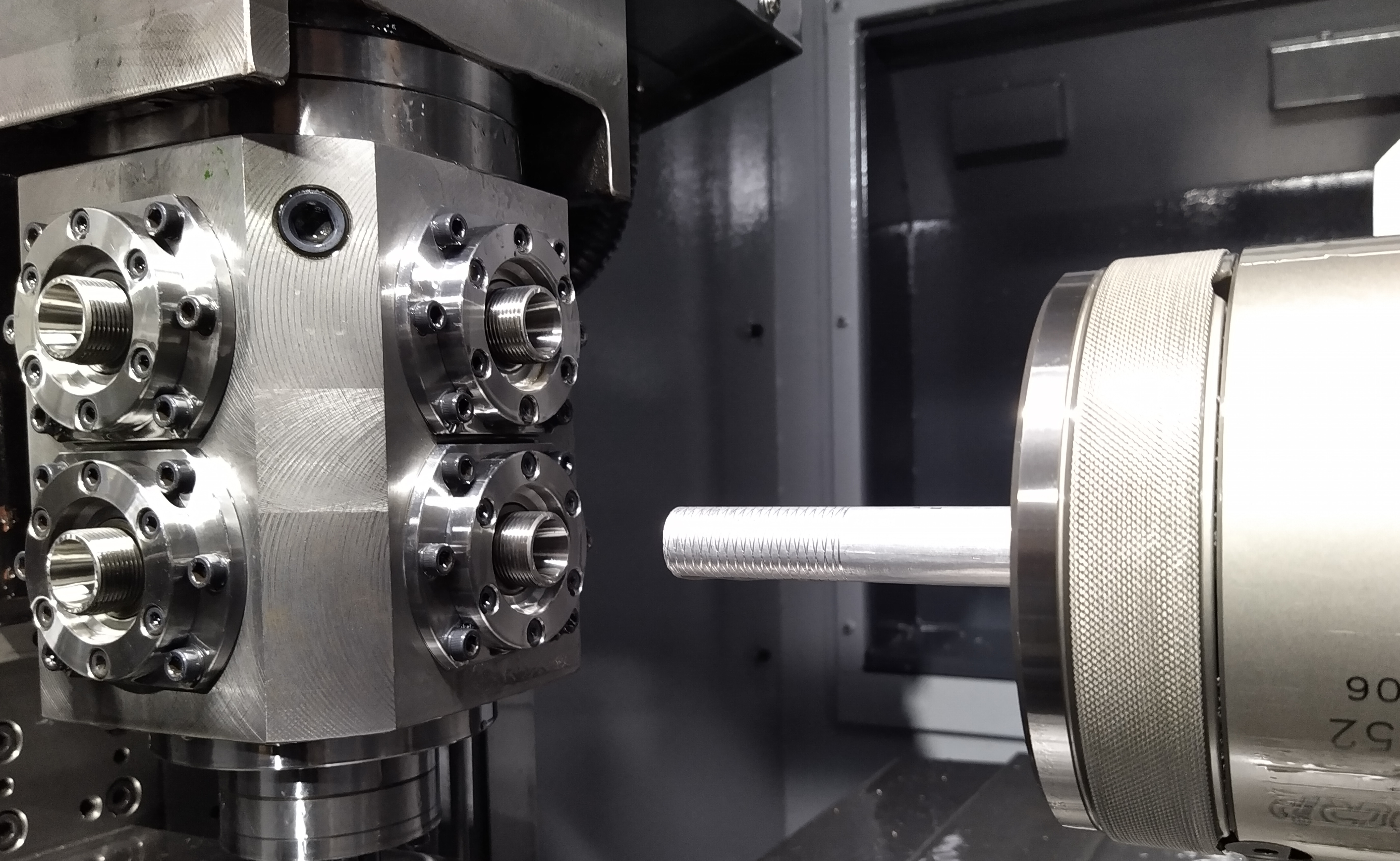

Power Turret

Power Turret with 12 station in Sauter BMT 55 system to support various machining tasks for more industries requires, enhance the main spindle capability with powerful cutting tool, easy to set up any kinds of tool by BMT-55 interface.

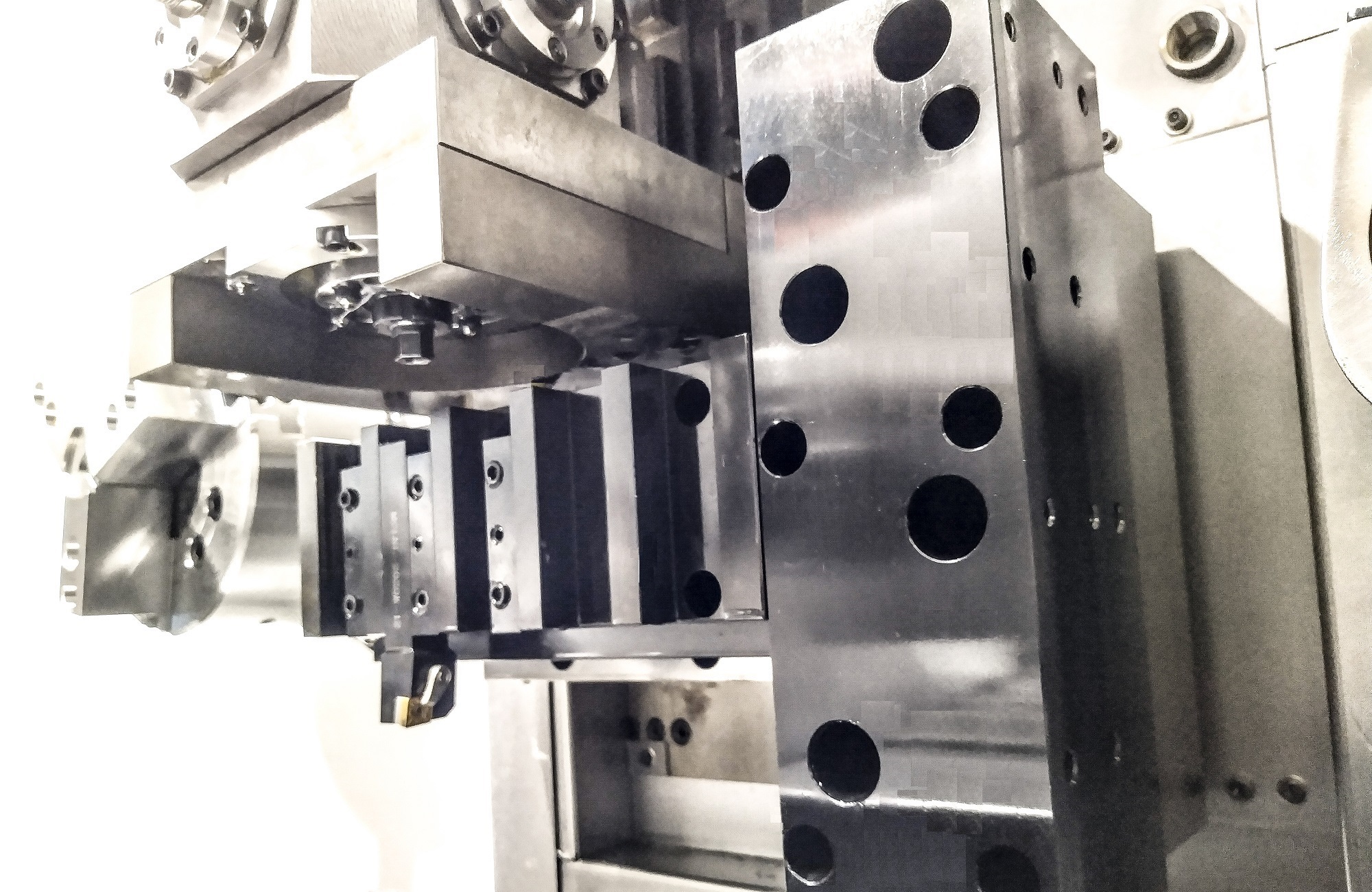

B axis Power Tools

The B axis rotation power tools is Ys. Precision Machinery own design, strong structure like milling spindle design to offer stable machining performance. Provide 8 pcs. power tool to machining parts in complex produce, rough produce, and finishing.

B Axis Machining Capability

2STB CNC multi-tasking turn mill center is a machining consultor that can offer machining in multi-tasking, work in efficiently and economical way. Easy to set up tool with ER-collet, all type of tools in general size. High machining performance suite producing complex precision part with fast cycle time.

Base Structure

It uses high tension FC-30 Meehanite cast iron to reducing vibration and stress relieving effectively in machine processing for superb surface finished, high rigidty structure can offer more stable maching performance. Real 90° Y axis structure on two systems increase machining flexibility, reducing processing issue.

Maintenance

Design to labor working friendly which provide large space for technician. Component in our machine which are international famous brand with standard spec for easy maintenance.

Functional option

Equip optional device like bar feeder, oil skimmer, coolant chiller, oil mist collector, high pressure coolant, gantry arm part collector, robot arm, optical encoder, angular position encoder, thermal senser, tool probe, CE certification model, voltage transformer, voltage stablizier, etc.

scroll for more

scroll for more

2STB CNC Multi-Tasking Turn Mill Center SPEC |

|||

|---|---|---|---|

| Controller | Fanuc 0i-TF PLUS | ||

| AXES SPECFICATION | SUB SPINDLE | ||

| X1/ X2-axis travel | 150/ 530 mm | Max. spindle speed | 4,500 rpm |

| Y1/ Y2-axis travel | ±35/ 436 mm | Spindle nose | A2-5 |

| Z1/ Z2-axis travel | 300/ 400 mm | Spindle bar capacity | Ø52 mm |

| X/ Y/ Z-axis servo motor power | 2.2 kw | Sub spindle motor | 7.5 kw |

| X/ Y/ Z-axis rapid travel speed | 25/ 25/ 30 m/ min. | C-axis positioning resolution | 0.001° |

| B-axis motor | 0.75 kw | SUB SPINDLE TOOLS | |

| SPINDLE | No. of O.D. turning tool | 5 sets | |

| Max. spindle speed | 4,500 rpm | O.D. turning tool size | □20 mm |

| Center height | 1,205 mm | No. of I.D. turning tool | 5 sets |

| Spindle nose | A2-6 | I.D. turning tool size | Ø20 mm |

| Spindle bar capacity | Ø52 mm | SUB SPINDLE LIVE TOOL | |

| Spindle motor power | 9 kw | No. of axial driven tool | 8 sets |

| C-axis positioning resolution | 0.001° | Axial driven tooling motor power | 2.2 kw |

| SPINDLE LIVE TOOLING TURRET | Max. axial driven tooling speed | 4,000 rpm | |

| Turret stations | 12-stations | Driven tooling size | ER-20 |

| O.D. turning tool size | □25 mm | COOLANT PUMP | |

| Max. driven tool speed | 6,000 rpm | 1st system flush pump | 2.1 kw |

| Driven tool motor power | 2.2 kw | 2nd system flush pump | 1.3 kw |

| No. of diven tool | 12 sets | 3rd system flush pump | 1.3 kw |

| Collet size | ER-25 | HYDRAULIC UNIT | |

| Tool holder & tool size | BMT 55 | Hydraulic pump | 2.25 kw |

| TANK CAPACITY | MACHINE DIMENSION | ||

| Hydraulic tank | 70 L | L x W x H (Include chip conveyor) | 4,050 x 2,190 x 2,300 mm |

| Coolant tank | 320 L | Weight (Include chip conveyor) | 6,800 kg |