The 2ST 36 model CNC Turn Mill machine clamped workpiece by the collet for processing. The material moves back and forth, product is processed through the linear or swinging motion of the tool. Various machining tool configuration, fast tool change without turret indexing, tool easy to replace in modularization. Complete all the cutting procedures at one setup time, avoid tolerance of workpiece exchanging. Equip bar feeder to increasing production efficiency in mass production. The applications of CNC turn mill machine is suit in cutting for the future, and match machining requirements in various industries, such as aerospace technology, medical tech, hardware and electronic.

2ST 36 model CNC Turn Mill Machine Feature

Structure

2ST 36 model CNC turn mill machine equip 2 equal size spindles and powerful spindle motor, max bar capability 36 mm, provide full machining ability in once setup by twin spindles. 2ST 36 model uses high tension FC-30 Meehanite cast iron to reducing vibration and stress relieving effectively in machine processing for superb surface finished, high rigidty structure can offer more stable maching performance.

Tooling System Configuration

2ST 36 model CNC turn mill machine is equipped powerful tool configurations. The front and back of the workpiece in processing, shortens the cycle time greatly and complete complex workpieces in one setup, high rigidity structure to provide stable cutting ability.

Controller

Taiwan controller manufacturers, SYNTEC , easy reading and operation interface, program editing in simple way, 15" display mounted with SYNTEC, large monitor size can show more inforamtion, new generation host structure for future functional extension, an economic choice. ( FANUC Option )

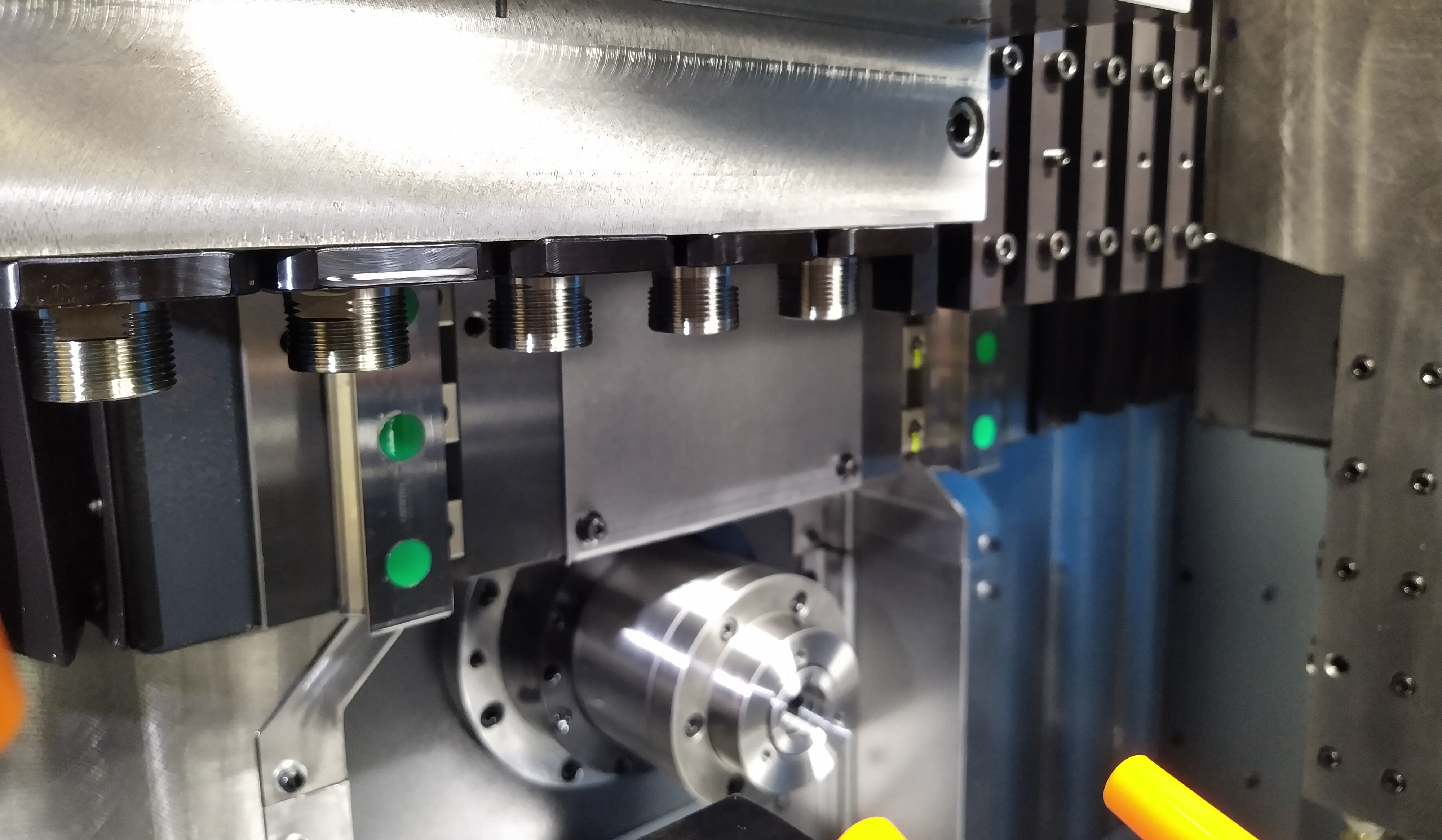

Main Spindle Tooling System

6 O.D. turning tools holder of □12 mm, 5 I.D. turning tools holder of Ø25 mm, 9 milling power tools of ER-20 interface (axial side x 4 + radial side x 5). Easy to replace in comment size, production exchange to other machine in normal. The tooling specifications are no worry about installing from your side, which is costs reducing.

Main Spindle Cutting Capability

The 2ST 36 model CNC turn mill machine is equipped 9 driven tools, 6 O.D. turning tools and 5 I.D. turning tools. Enhance the machining ability for the front. Processing workpiece front and back sides in hexagonal, polygonal, short part at one setup to shorten cycle time.

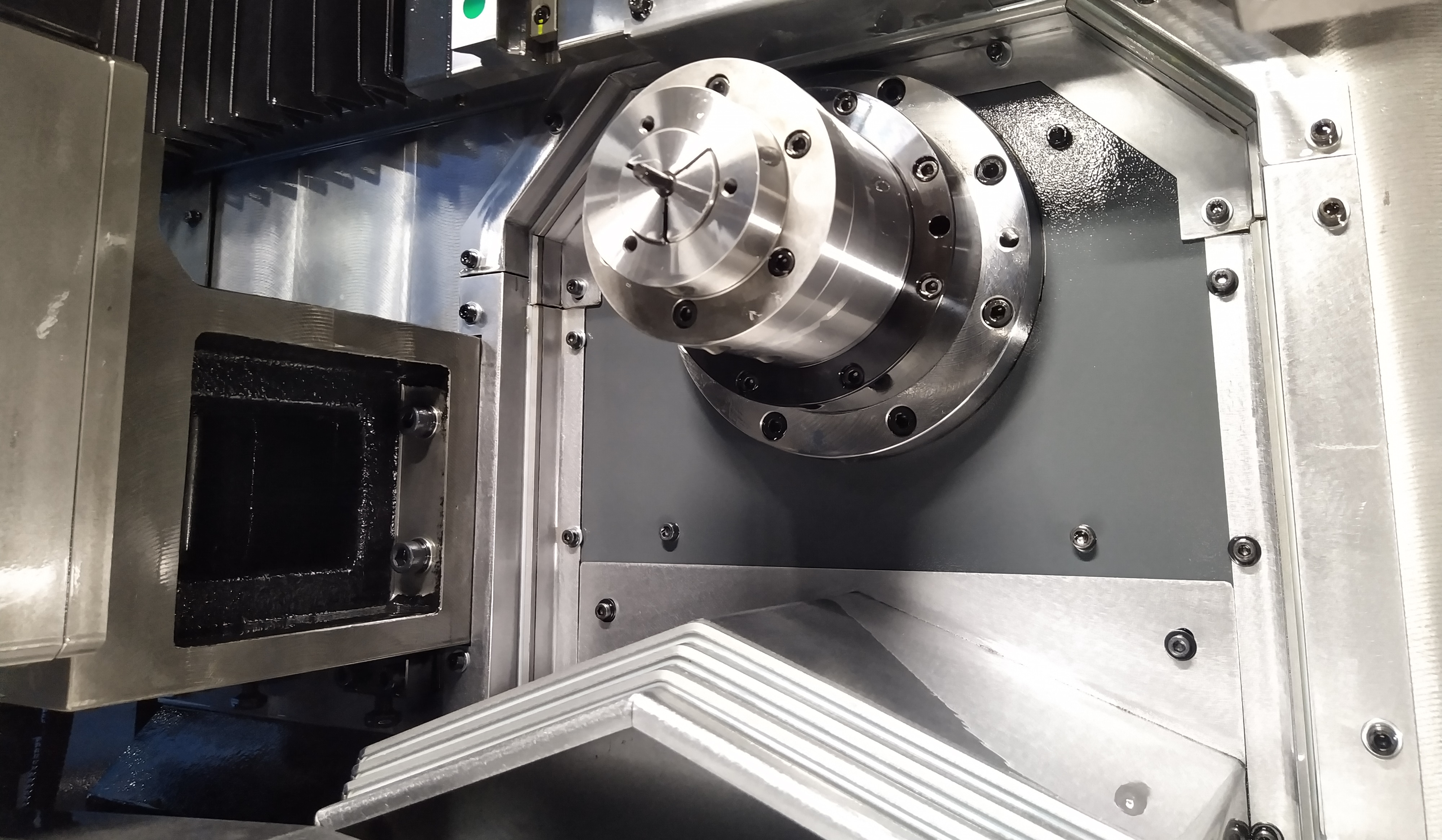

Full anti-Chips Spindle Cover

Movable spindle with full anti-chips cover, which strengthen the chips removal capability, improves the machine lifetime and the processing efficiency.

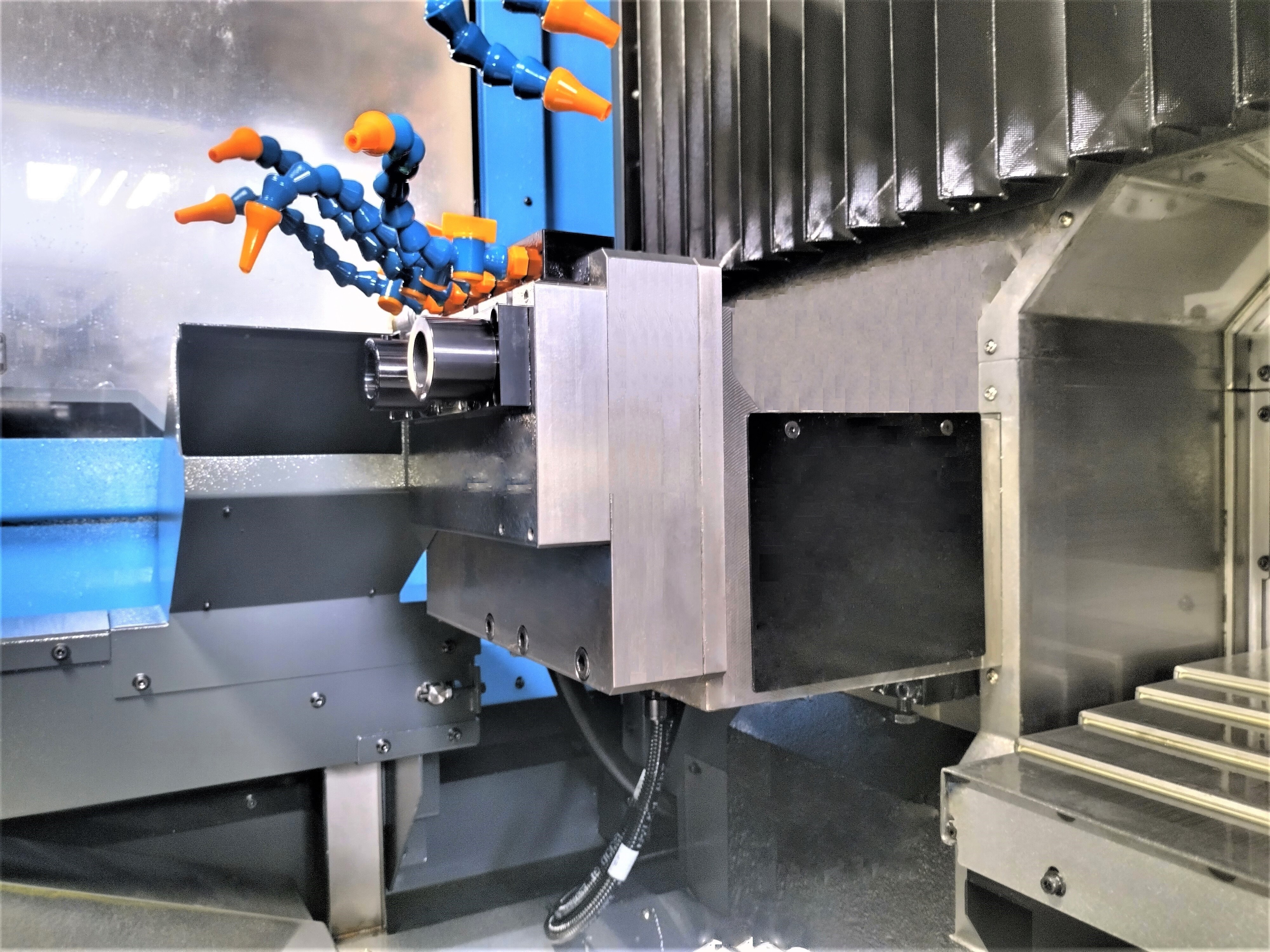

Sub Spindle Tooling System

Equipped with 4 axial driven tools, place turning tool adapters in option, back processing is diversified for complex workpieces can be cut easily. (Turning tools adapter option)

Sub Spindle Cutting Capability

Axial driven tools with strong structure to enhance the machining performance which increase the flexibility of the back processing, high rigidity back cutiing tool structure to provide stable cutting ability.

Part Collect System

2ST 36 with finished product collecting system in auto, which is convenient for users to operate. It is easy to use for full automation processing whitch unloading the finished part from sub spindle, transfer the part by conveyor to the part collecting area.

Functional Option

Equip optional device like bar feeder, oil skimmer, coolant chiller, oil mist collector, high pressure coolant, gantry arm part collector, robot arm, optical encoder, angular position encoder, thermal senser, tool probe, CE certification model, voltage transformer, voltage stablizier, etc.

左右滑動看表格

左右滑動看表格

2ST 36 model CNC turn mill machine |

|||

|---|---|---|---|

| Controller | Taiwan Syntec 220TB | ||

| MACHINE CAPABILITY | MAIN SPINDLE TOOLS | ||

| Max. turning Length | 100 mm | No. of O.D. turning tools | 6 sets |

| Max. machining diameter | Ø36 mm | O.D. turning tool | □12 mm |

| AXIS SPECIFICATIONS | No. of I.D. turning tools | 5 sets | |

| X1/ X2-axis travel | 170/ 420 mm | I.D. turning tool size | Ø25 mm |

| Y1-axis travel | 510 mm | MAIN SPINDLE LIVE TOOLING | |

| Z1/ Z2-axis travel | 190/ 330 mm | No. of axial driven tools | 4 sets |

| X/ Y/ Z-axis rapid travel speed | 30 m/ min. | Axial driven tooling motor power | 2.4 kw |

| Z1/ Z2-axis servo motor power | 1.1 kw | Max. axial driven tooling speed | 6,000 rpm |

| X1/ X2-servo motor power | 1..7/ 1.1 kw | Axial driven tooling size | ER-20 |

| Y1-servo motor power | 1.1 kw | No. of Radial driven tool | 5 sets |

| MAIN SPINDLE | Radial driven tooling motor power | 2.4 kw | |

| Max. spindle speed | 6,000 rpm | Max. radial driven tooling speed | 6,000 rpm |

| Center height | 1,055 mm | Radial driven tooling size | ER-20 |

| Spindle nose | A2-4 | SUB SPINDLE LIVE TOOLING | |

| Spindle bar capacity | Ø36 mm | No. of axial driven tools | 4 sets |

| Spindle servo motor | 7.5 kw | Axial driven tooling motor power | 2.4 kw |

| C-axis index positioning | 0.001° | Max. axial driven tooling speed | 6,000 rpm |

| SUB SPINDLE | Axial driven tooling size | ER-20 | |

| Max. spindle speed | 6,000 rpm | O.D. tool adaptor (option) | I.D. tool adaptor (option) |

| Spindle nose | A2-4 | COOLANT PUMP | |

| Spindle bar capacity | Ø36 mm | 1st System flush pump | 1.3 kw |

| Spindle servo motor | 5.9 kw | 2nd System flush pump | 1.3 kw |

| C-axis index positioning | 0.001° | HYDRAULIC UNIT | |

| TANK CAPACITY | Hydraulic pump | 0.75 kw | |

| Lubrication tank | 4 L | MACHINE DIMENSION | |

| Hydraulic tank | 25 L | L x W x H (Include chip conveyor) | 3,320 x 1,560 x 2,100 mm |

| Coolant tank | 240 L | Weight (Include chip conveyor) | 4,600 kg |